Tips for steel pipe corrosion protection in applications

Generally speaking, metal corrosion occurs when metal is exposed to moisture and other elements or chemicals. As it is generally a natural process for various types of carbon steel pipes in applications, it can lead to a severe decrease in the functionality and esthetics of metal products. Therefore, it is believed that a successful corrosion control program is a never ending practice. It begins with an effective design and installation of the pipeline, executing corrosion control methods, and maintaining and monitoring the lines.

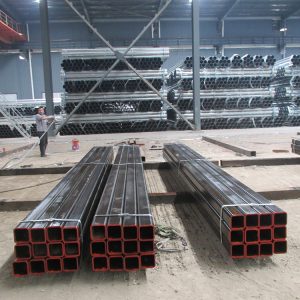

It can not be denied that steel pipe is a product that tends to be prone to corrosion in service especially under certain harsh conditions. In real life, corrosion and repair of corrosion damage are multi-billion dollar problems every year. For example, the oil and petroleum industries widely use black steel pipe for convey large quantities of oil through remote areas. Although it doesn’t have a corrosion resistant layer like the galvanized steel pipes or other welded steel pipes, its high fire resistant performance plays an important role in fire sprinkler system. In most cases, how to extend the service life of black steel pipe in applications has become a topic issue for users now and then. In practical applications, there are many types of metal surface treatments for steel pipe in a mill today. For one thing, fabrication services such as metal finishes will generally add to delivery time on your order. For the other thing, a proper coating can become an effective protective film for steel pipe against any damages or breakdown in order to extend the service life in applications.

Cold rolled steel pipe generally has the rational cost effective in the market. As a rule, cold rolled steel pipe repairs take on various forms, ranging from temporary clamps to the replacement of entire piping systems. In many examples, the denial of a corrosion problem results in multiple or staged repairs over years, wasting valuable time that could have otherwise been used to correct the problem and minimize far greater corrosion damage. All too often, one or multiple individual failures are fixed without further investigation into the hidden cause. For professional steel pipe manufacturers, the absolute reliance on favorable but typically inaccurate corrosion rate data presented by corrosion coupons, often in contrast to blatantly obvious physical indicators such as thread leaks and high rust deposits, allows a high corrosion condition to continue unabated, thereby producing a much greater repair problem once the true corrosion problem is finally realized.

Tel: +86 18202256900 Email: steel@fwssteel.com