manufacturing cost of steel industry rose and benefit of enterprises decreased

Steel production of rectangular hollow section keeps growing. From January to September, China’s crude steel output was 748 million tons, up 8.4% year on year. Pig iron output was 612 million tons, up 6.3% year on year. Steel output (including repeatable materials) was 909 million tons, up 10.6 percent year on year. Both imports and exports fell. From January to September, China exported 50.31 million tons of steel, 2.67 million tons less than the same period last year, down 5.0%. Imports of steel totaled 8.75 million tons, down 1.22 million tons or 12.2 percent year on year. From January to September, China imported 784 million tons of iron ore, 19.01 million tons less than the same period last year, down 2.4 percent.

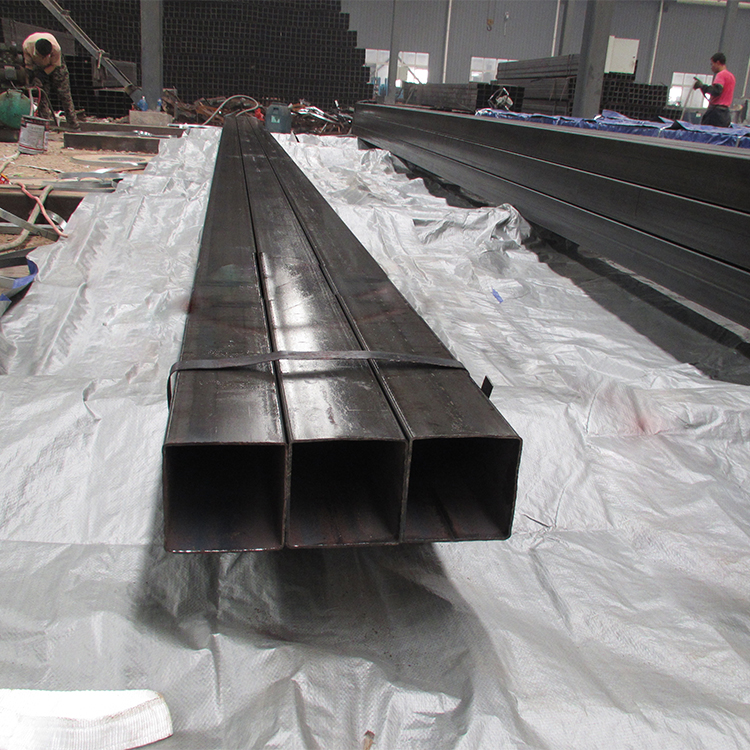

Steel prices have fallen. From January to September, the China steel price index (CSPI) composite index averaged 108.58 points, down 7.17 points year-on-year, or 6.2 per cent. The long material index averaged 114.61 points, down 5.0% year on year, and the plate index averaged 104.81 points, down 7.5% year on year. Manufacturing costs of cold rolled steel pipe have risen markedly. Since the beginning of this year, the prices of domestic iron concentrate, imported iron ore, scrap steel, coking coal and other major raw materials have generally risen and continued to run at a high level. From January to September, compared with the same period last year, the procurement cost of main raw materials increased by 31.7% for imported mild steel tube, 21.5% for domestic iron concentrate and 8.8% for scrap steel.

Enterprise benefit drops obviously. From January to September, the sales revenue of member enterprises reached 3.18 trillion yuan, up 11.6% year on year.The total profit reached 146.6 billion yuan, down 32.0% year on year;The margin on sales was 4.6%, down 3 percentage points from a year earlier. In the first three quarters of this year, driven by the government’s measures to stabilize growth, major projects were started in various localities, creating a better market environment for the steel industry. Steel pipe suppliers have grasped market opportunities to met market demand, achieved stable production and increased production, and actively promoted ultra-low emission transformation, actively explored merger and reorganization paths, and achieved phased results. More and more enterprises have met the ultra-low emission targets. The reorganization of baowu and masteel is another achievement in the process of merger and reorganization. Some problems are existing in the operation of steel pipe industry.

Tel: +86 18202256900 Email: steel@fwssteel.com