How to see welded steel pipe widely used in building frames for such a long time in history

In the current steel pipe market, there are various types of welded steel pipe available in various projects, such as black steel pipe, electrical conduit, straight seam welded steel pipes, helical seam submerged arc welded steel pipes and high frequency welded steel pipes and etc. As the earliest historical records show that during the first century A.D., the first lead pipes was produced in Europe. So far, welded steel pipe has experienced continuous evolution and functional innovation. As for welded steel pipe, it can be dated back to the early 1800s. Following William Murdock’s successful lighting system, there appeared a series of innovation and development for metal pipes. In that regard, welded steel pipe has a long story in history since then.

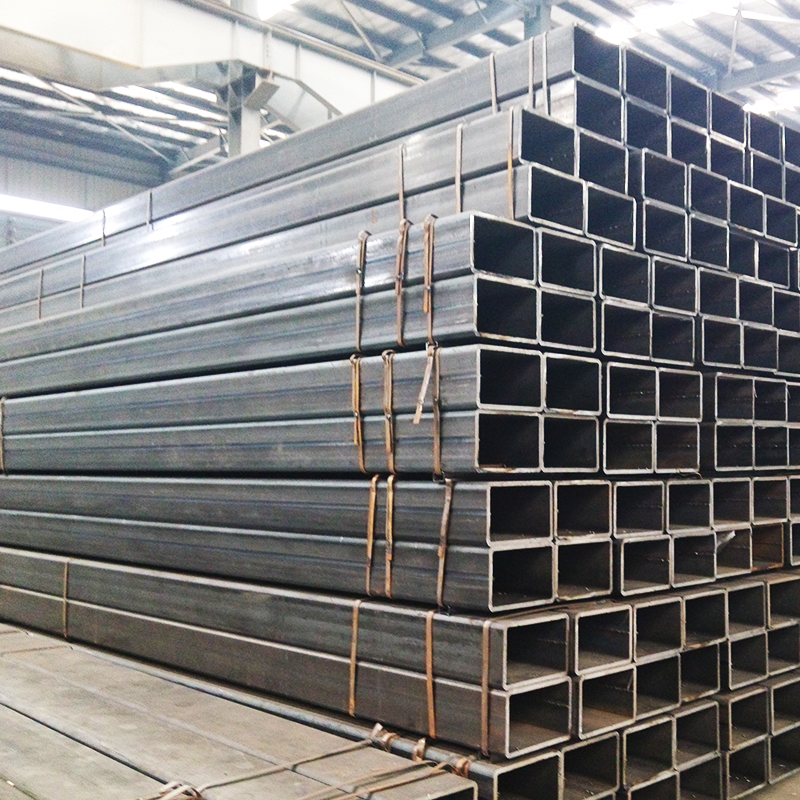

In the modern society, steel frame building materials are growing in popularity, and in some places around the world, steel is actually displacing timber as the primary framing material for both residential and non-residential buildings. At present, more and more building owners, designers, architects, and general contractors have opted for metal in commercial construction projects over other materials mainly for its energy efficiency, low maintenance, and durability. In the current steel pipe market, China hollow section tubes have become the predominate material widely used in a variety of construction projects, such as bridges, buildings, towers, and other structure applications. Furthermore, due to the great strength, uniformity, light weight, ease of use, and many other desirable properties, welded steel pipe has been widely used in a variety of practical purposes. In the United Kingdom, for instance, 90% of one-story industrial buildings and 70% of multiple story industrial and commercial buildings make use of structural steel pipes today.

Besides, in some particular applications, some other key attributes, such as striking beauty, clean look, and versatility in both new and retrofit construction are becoming helpful to firmly establish steel as the material of choice for institutional, commercial and education building projects. For example, hot dipped galvanized steel pipe is such cost-effective in the market that it has become the favor for many contractors in construction projects in the modern times. For one thing, the galvanization process protects the steel from rusting damage that can occur during transportation, installation and service. The zinc layer on the surface of pipe can form a barrier protection for steel products to extend the service life in applications. For the other thing, this layer is also resistant to wear and scratch, which makes the steel look more attractive.

Tel: +86 18202256900 Email: steel@fwssteel.com