How to manufacture hollow section tubes in a mill

In the modern times, hollow section tubes are very popular and widely used as structural materials in some large construction projects around the world. Especially in the recent years, China hollow section tubes have a great demand in the global steel pipe market due to their competitive advantages. Every year, a lot of customers around the world come to China for their desired steel products. However, whether you have tried to learn about how to manufacture hollow section tubes in a mill?

Generally speaking, hollow sections have two major categories in the current steel pipe market: seamless steel pipe and welded steel pipe. Both of them are widely used in a wide range of applications in our society today. Seamless hollow sections are made in two phases, i.e. the first phase consists of piercing an ingot and the second step considers the elongation of this hollow bloom into a finished circular hollow section. And then, the tube will go through a sizing mill to give it the required diameter. Nowadays, welded hollow sections with a longitudinal weld are mainly made employing either electrical resistance welding processes or induction welding processes. As a rule, a strip or plate is formed by rollers into a cylindrical shape and welded longitudinally. The edges are heated, e.g. by electrical resistance, then the roller push the edges together, resulting in a pressure weld. The weld protrusion on the outside of the tube is trimmed immediately after welding.

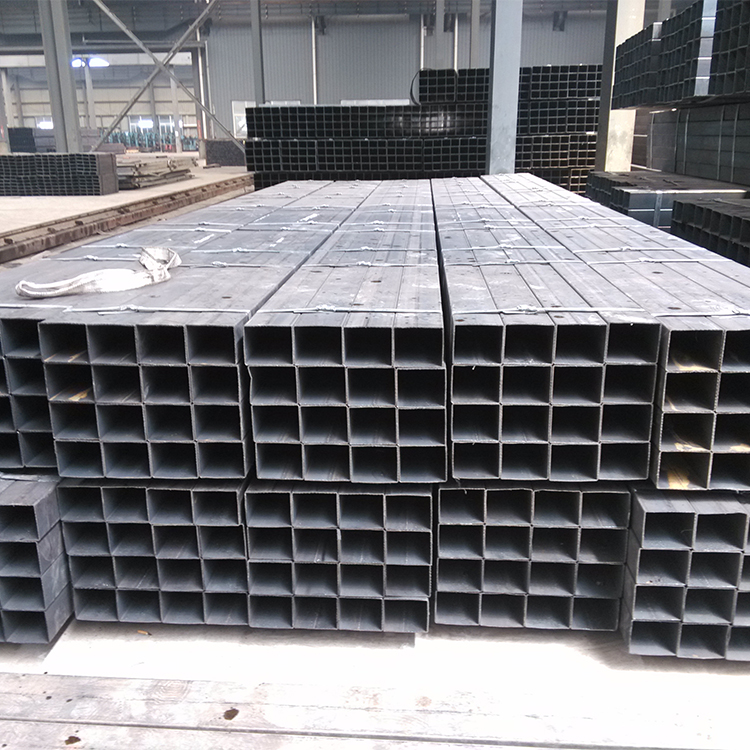

Rectangular hollow sections also called rectangular steel pipes in the current steel pipe market, which are made by deforming circular hollow sections through forming rollers. And this forming process will be done by hot or cold, using either seamless or longitudinally welded circular hollow sections. Although it is common practice to use longitudinally welded hollow section, for the very thick sections, seamless sections may be used. In addition, square or rectangular hollow sections are sometimes made by forming a single strip to the required shape and closing it by a single weld, preferably in the middle of a face. And some large circular hollow sections are also made by rolling plates through a so-called U-O press process in a mill. After forming the plates to the required shape, the longitudinal weld is made by a submerged arc welding process. Another process for large hollow section tubes for steel pipe manufacturers in China is to use a continuous wide strip, which is fed into a forming machine at an angle to form a spirally formed circular cylinder. The edges of the strip will be welded together by a submerged arc welding process to produce spirally welded tube in a mill.

Tel: +86 18202256900 Email: steel@tjdpbd.com