How to identify different types of structural steel pipe in the market?

With the further development of the steel market, welded steel pipe has relatively complete types for different customers to make the right choice. Welded steel pipe has good quality in comparison with PVC pipe as it has better bearing compression performance in certain actual applications. Generally speaking, there are many different approaches for identify different types of welded steel pipe in the market. Professionals consider whether the steel pipe is straight seam or spiral welded. Others may divide the material into its purpose e.g. mining, oil drilling, agricultural, or manufacturing.

One of the more common ways of classifying welded steel pipes is by looking at the process. In other words, classifying steel pipes according to production methods and/or sub-processes. The results fall into one of three classifications. These are:

1. Electric-Resistance Welded (ERW): ERW is either high or low frequency. Restricted to a size of a maximum of approximately 24” in diameter, this type of welded steel pipe is the result of longitudinally welded HR coil.

2. Longitudinal (LSAW or DSAW): The main substrate for this method is heavy steel plate. Producers use one of two methods, submerged arc welded (SAW) and the double submerged arc welded (DSAW). The resulting flat plate features a straight seam stretched the full length of the pipe. Standard sizes for this type of pipe range between 12m and 18m. By using this method, the weld quality is high with few defects.

3. Spiral Welded or Spiral Welded Longitudinal: Spiral welded, like the name indicates, is the result of a circular motion. China steel tube manufacturer generally takes the plate, and winds and welds the substrate of an HR coil or steel plate in a spiral. This method is called helical submerged arc welded (HSAW). The resulting product is longer and thicker than other methods. Overall, this method is favored because it proves to be simple, efficient, cost-effective and fast.

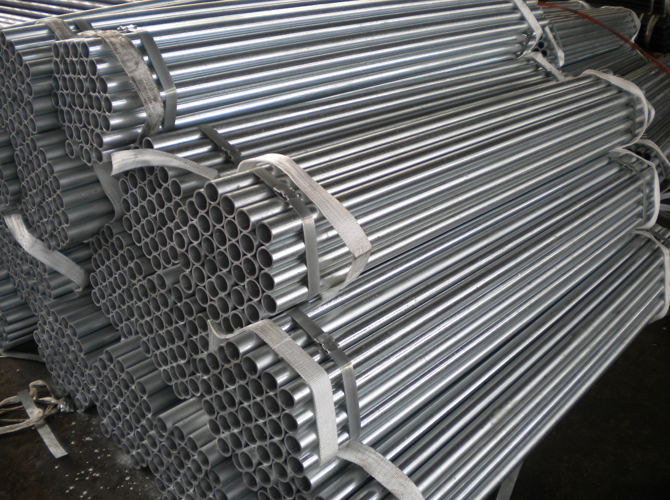

How to choose the proper welded pipe for your next project? First of all, you should have a basic command of professional products involving different actual applications. As a rule, good quality of qualified pipe must strictly follow a certain production standard in the manufacturing process. Besides, high quality materials and advanced processing technology will somewhat greatly enhance the performance of pipes for various actual purposes. For instance, when we are purchasing hot dipped galvanized steel pipes, besides its raw materials, pipe shapes as well as the welding processing conditions, also should also pay particular attention to the zinc layer coated around pipes. Furthermore, adequate preparations for certain professional knowledge about products in advance will greatly reduce the risk of problems in the practical applications in the future as well as avoid many unnecessary losses. Next, before making a decision on an order, you should make the good judgment on the steel pipe manufactures’ official websites. For one thing, it will give customers more information so as to facilitate customers getting a better knowledge of products. For the other thing, it will benefit manufactures to have closer relationship with potential customers. Last but not the least, with reference to the actual application, different application requirements generally need specific pipe specifications. What you should do in the actual purchase is to carefully refer to the quotation sheet from the manufacturers. Meanwhile, by comparing the different steel pipe prices, you can also make a reasonable budget for the procurement costs. In a sense, this will help us to avoid all kinds of blind spots in the procurement, as well as to maximize the cost savings, in order to ultimately buy the ideal products.

Tel: +86 18202256900 Email: steel@fwssteel.com