Challenges to more sustainable methods

Transitioning to more sustainable methods of production is a complex process for steel pipe producers. While there are many benefits to adopting more sustainable practices, there are also significant challenges that companies must overcome in order to make the transition successfully. One of the biggest challenges that steel pipe producers face is the cost of implementing new technologies and processes of thinner wall steel pipe. While there are many innovative solutions available, many of these require significant investment in new equipment and infrastructure. This can be a significant barrier for companies that are already operating on tight margins. Additionally, many companies may be hesitant to invest in new technologies if they are unsure about the long-term economic benefits.

Another challenge that steel pipe producers face is the need for skilled workers who are familiar with sustainable production methods. Many of the new technologies and processes that are being developed require specialized knowledge and training to operate effectively. This can be a challenge for companies that are struggling to find qualified workers with the necessary skills and experience. In addition to these challenges, there may also be resistance from stakeholders who are skeptical about the benefits of sustainable production methods. For example, some employees may be resistant to change of Api 5l Spiral Pipe if they are comfortable with traditional methods of production. Additionally, customers may be hesitant to pay more for sustainable products if they do not see a clear benefit.

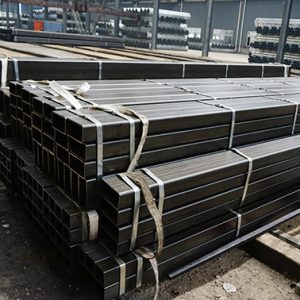

Finally, there may be regulatory challenges that companies must navigate when transitioning to more sustainable methods. For example, there may be new environmental regulations that require companies to reduce their emissions or waste output. Compliance with these regulations can be costly and time-consuming, and may require significant changes to production processes. Despite these challenges, there are many reasons why steel pipe producers should consider transitioning to more sustainable methods of production of Gi square steel pipe. In addition to reducing the environmental impact of the industry, sustainable production methods can also lead to cost savings, improved efficiency, and increased customer satisfaction.

To overcome these challenges, steel pipe producers need to work closely with their stakeholders to develop a clear strategy for transitioning to more sustainable methods. This may involve investing in new technologies and infrastructure, training employees on sustainable production methods, and engaging with customers to ensure that they understand the benefits of sustainable products like cold rolled steel pipe. Additionally, companies should be proactive in addressing regulatory challenges by working closely with government agencies to ensure that they are in compliance with all relevant regulations.

Tel: +86 18202256900 Email: steel@fwssteel.com