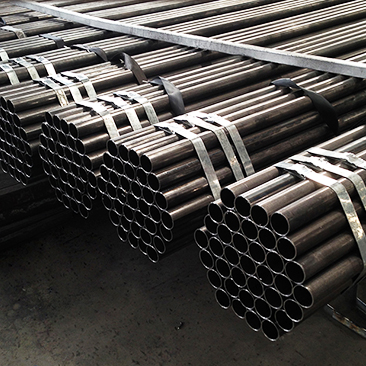

Black steel pipe in applications

Today, there are various kinds of steel pipes available both in domestic and international markets for your selection. And black steel pipe is one of the most popular pipes among consumers. Black steel pipe is made of steel that has not been galvanized. Its name generally comes from its dark-colored iron oxide coating on its surface. It has been widely used in certain applications where there are not so serous requirements of galvanization for pipe protection.

In the steel pipe industry, there is certain big difference in a few aspects between black steel pipe and hot dipped galvanized steel pipe. Specifically, in some practical application sectors, black steel pipe’s strength performance makes it ideal for transporting water and gas in rural and urban areas, as well as widely used for conduits to protect electrical wiring. In oil & petroleum industries people usually use black steel pipe for moving large quantities of oil through remote areas. Moreover, black steel pipe requires very little maintenance work in usages. As to steel pipe price, black steel pipe is relatively cheap in comparison with galvanized steel pipe due to the high cost of the galvanized steel pipe processing.

Here, as a professional steel pipe manufacturer in China, we would like to give you some useful tips for the maintenance of black pipe in certain applications. Generally speaking, you may need to prepare the following things, like wire brush, rags, acetone, rusty-inhibitive primer, paint and so forth in advance. 1)To clean the surface of the black pipe: you are advised to use the wire brush to wipe down the oily areas with a cleaning agent to scrub the areas with rust or loose paint. Because there will be some dust on the pipes, it will influence your work effect if you don’t wipe it well. 2) To apply a thin layer of rust-inhibitive primer: You can use the spray can to make it quick and easy to be done. Besides, you should re-coat with the second layer of primer on the first layer having dried actually. Next, spray on your first layer of topcoat. To ensure the even coverage, you are advised to move the spray from side to side. Do not apply the second coat when the first layer is not fully dry. 3) To keep no damaged paint on the surface of the black pipe. As we all know, the damaged part will be the fragile part that is subject to being damaged and corroded so as to affect the normal function of the black pipe in practical applications in life.

Tel: +86 18202256900 Email: steel@fwssteel.com