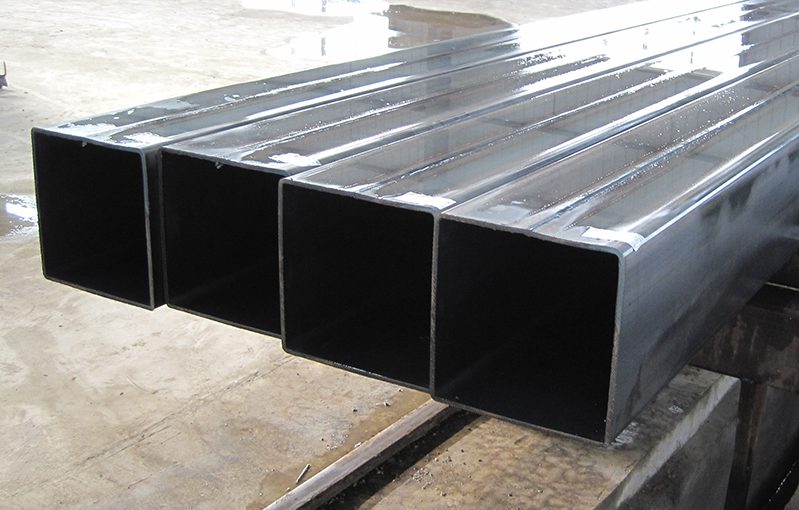

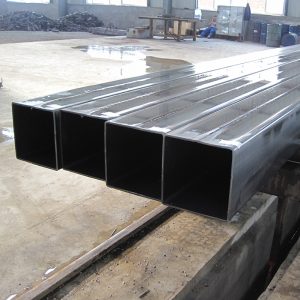

Product Name:steel square pipe and rectangular tube

Size OD:20×10-300x400mm and 20×20-400x400mm

Thickness: 0.5~12.75mm,

Length:1-12m or as request

Steel Material:Q195, Q235, Q345, Fe310, Fe360, St33, St37-2, SS330, SS400, STK400, STK500, S235, S275JR, S355, ASTM A53, ASTM A513

Standard:ASTM, ASME, DIN, GB, JIS, ASNI, BS

Usage: Construction, bridge, highway, windows of model steel door, machinery, chemical industry, supermarket goods shelf.

Ends: Usually Plain ,But Can Be Beveled Or By Your Choice

Surface:oiled, black painting, galvanized, annealed

Technique:ERW and Hot Rolled

Packing:

1) 20ft container: 26tons (Can load 5.8M Max)

2) 40ft container: 26tons (Can load 12M Max)

3) more than 100tons:can pack by bulk vessel

4)as your requirement