In the steel pipe market, there are various different types of welded steel pipe available in various applications. It is widely used in the construction industry, and also be found in a variety of manufacturing and industrial applications. In plumbing system, steel pipe is applied to conveying liquids and gases for commercial and residential buildings, as well as in municipal water supplies. In construction field, it is also used for a structural component for scaffolding and framing systems.

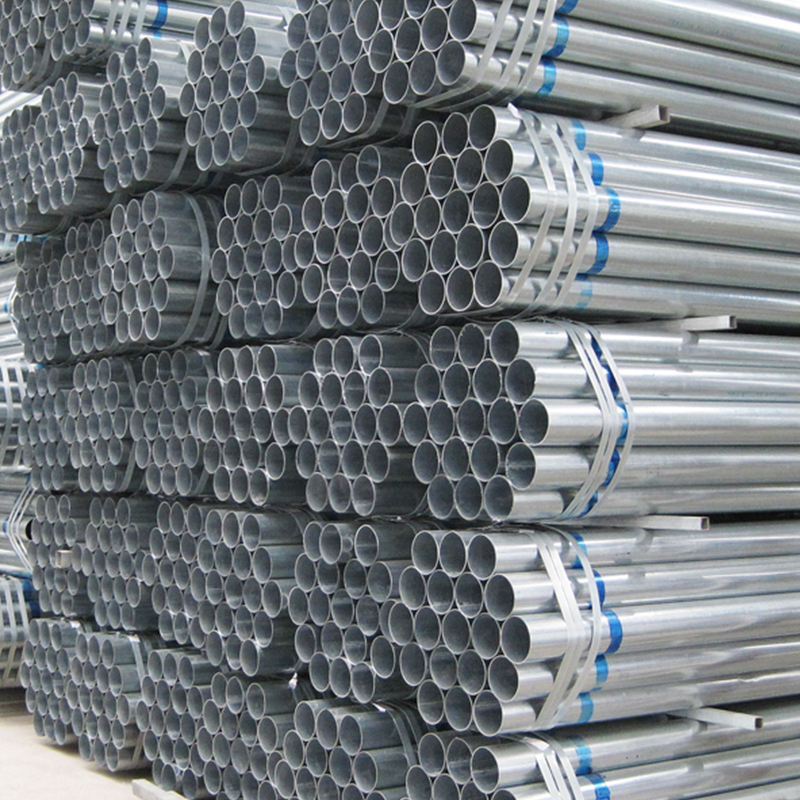

Hot dipped galvanized pipe has been considered popular a lot among many users today. For one thing, the galvanization process protects the steel from rusting damage that can occur during transportation, installation and service. The zinc layer on the surface of pipe can form a barrier protection for steel products to extend the service life in applications. For the other thing, this layer is also resistant to wear and scratches, which makes the steel look more attractive. Furthermore, with the layer of protection, pipes can be used in outdoor areas, and can withstand the harm from some of the environmental effects. Galvanized steel pipe is used in many outdoor applications such as fencing, fence posts and water-supply pipes.

As a rule, proper steel tube material, type and size for a given application and type of fitting is critical for efficient and trouble free operation of the fluid system. Furthermore, it is very important for you to choose the proper type of steel pipe for your hydraulic system in order to achieve an optimum combination of efficient and cost effective performance. Due to the abrasive nature of many fluids and their various temperatures, it is important to use the proper piping materials. Mild steel tube which typically has a chemically treated surface is recommended for hydraulic applications. Using steel tube is important because other materials such as galvanized pipe will corrode over time. Steel alloy pipe should be used for all components of a hydraulic piping system. This includes couplings, flanges, as well as steel nipples.

In recent years, many users choose welded steel pipes for its high quality, cost-effective and other good performance. It can not be denied that the low carbon or low alloy steel used for pipelines is strong, resistant to defects, and relatively easy to fabricate into pipes and pipeline. Thus, that may be the reason why the welded steel pipe is so popular among people at home and abroad. However, the application fields of welded steel pipe are expanding, which will also confront steel pipe manufacturers fierce competition in steel pipe market.