Do you know the powder coating process?

Speaking of powder coating process, it is clear that this method is widely used in construction industry. Actually, it is a dry painting process that is mainly used for coating metal. Firstly, do you know what is powder paint? You can read the article ‘Do you know the technology of powder paint?’ for your reference. There are several methods for applying powder coating. Spraying electro-statically is the most common method. Heat is used to melt the powder, causing it to flow. At last, the fluid can form a thin film and eventually dry to a hard, solid shell. Before starting the job, we should prepare the surface that is the most important step. Metal surfaces should be thoroughly cleaned to remove oils or grease. Metal will be rinsed in an acid solution after removing to etch the surface, which can help to ensure proper adhesion during powder coating process.

What is the next step for the process? All right, it is the actual powder application. The application methods vary in different types of powder being used. We can divide the media into two main types that is thermoplastic powder and thermoset polymer relying on heat curing with different ways. Do you know the specific process about this two types? For thermoplastic powder, it is usually used to heated work piece such as hot dipped galvanized steel pipe. The hot metal causes the powder to melt, flow and then harden upon cooling. While this method does not undergo any chemical change. In order to avoid any uneven spots on the surface, reheated method must be involved in the overall process.

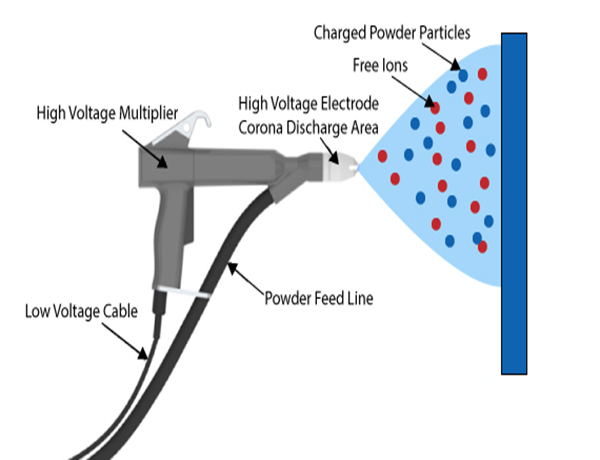

For thermoset polymer, the condition is required strict that is applied to the work at room temperature, then heat-cured in an oven. The range of the temperature is around 320-410 degrees Fahrenheit. The phrases include melting, flowing, forming and so on. For black steel pipe, the process is not very complex. Discussing powder coating process, powder coating equipment will appear in our mind. In the powder coating process, we can use several types of guns to achieve the same purpose via different approaches. These tools are designed to fluidize the paint media.

A kind of equipment called fluidized bed is employed by lots of steel pipe supplier during the powder coating process. A tank is involved in the basic fluidized bed system to hold the powder. As air enters the tank, the charged powder is fluidized. An advantage of powder coating process over other traditional painting methods is that it can adds more thickness to the piece which is especially important for items. These items are meant to fit together after powder coating. Do these process inspire you to delve into this technology?

Tel: +86 18202256900 Email: steel@fwssteel.com

Previous: Galvanized steel coil